Wastewater Treatment & Collection Systems – Aeration & Biosolids

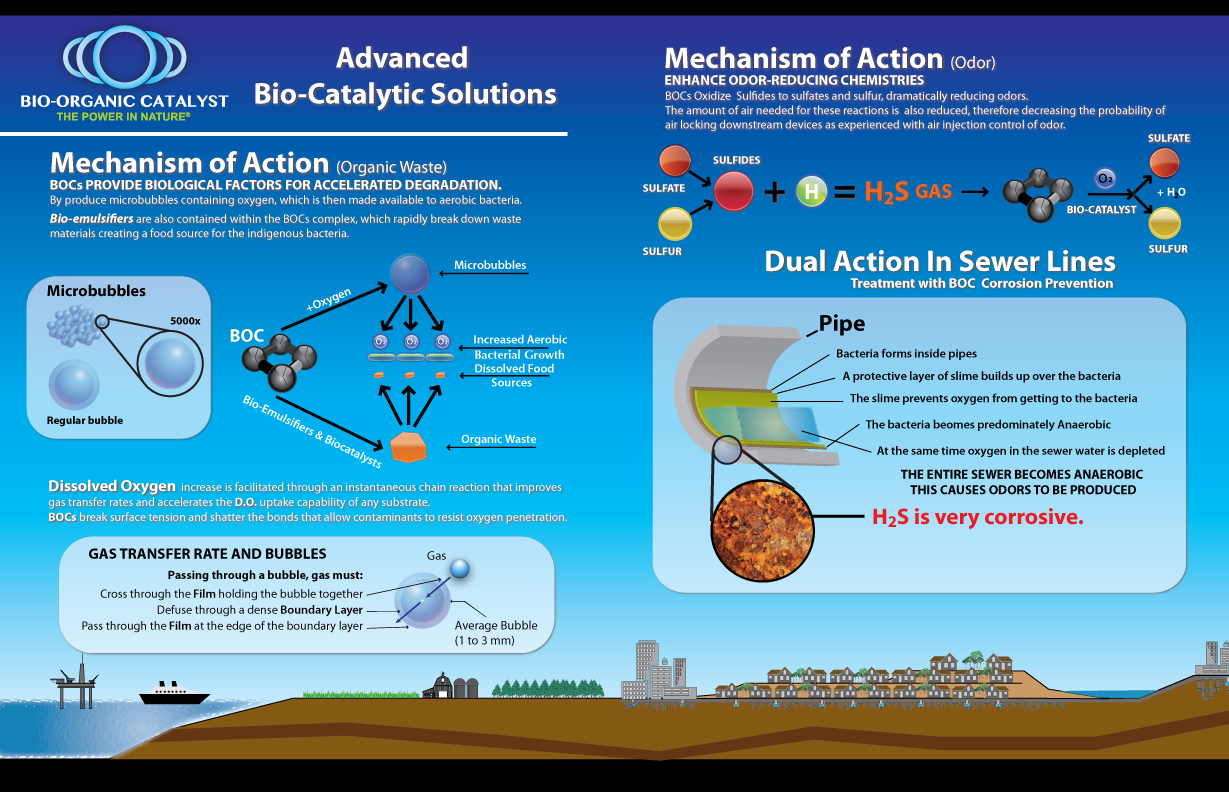

BOC biocatalytic compositions provide numerous benefits to all of the biological processes (aerobic and anaerobic) used to convert waste loadings into high quality discharges. The array of benefits made possible with BOCs can be applied system-wide to bring critical solutions to the fundamental challenges of operators. Odors, improving dissolved oxygen levels, reduction of organic loadings and biosolids, and improvements in discharges, are all operating parameters that can be improved with use of BOC.

BOC will allow a higher conversion of organic wastes, reduce energy usage, and lower sludge volumes. BOC will therefore substantially expand a wastewater facility’s total loading and capacity requirements. By greatly lowering the quantity of biosolids, processing and dewatering requirements are reduced. Transportation costs for hauling away these biosolids to landfills is likewise reduced.

BOC is unique in the ability to provide substantial improvements in dissolved oxygen levels, while simultaneously reducing the energy requirements of the aeration systems. This is both economically compelling, as well as critically important when the wastewater system is attempting to treat heavy organic loadings than the system is optimally designed.

BOC has phenomenal H2S gas (odor) reduction performance compared to other chemical or biological agent in the marketplace. Importantly, it also offers an ability to biologically reduce sewage upstream of wastewater treatment facilities. BOC is able to treat miles of sewer lines downstream of injection, cleaning the biological growth (slime layers) within the pipes which are the underlying biological sites for anaerobic conditions leading to Hydrogen Sulfide (H2S) formation, and creating higher bulk sewage dissolved oxygen levels.

Bio-catalysis of wastewater constituents (BOD, TKN) within the collection system, reduces the loading values prior to the wastewater treatment facility, thereby reducing aeration demands from BOD and TKN reductions. BOC has shown capabilities to lower H2S levels in sewer line repair/replacement that exceed the capabilities of all other chemical products on the market. This market application has proven to be quite compelling as the threshold levels of H2S for worker safety make these a crucial test of product performance against all competing, and typically toxic, chemical agents.

![]()

Watch this video on Unlocking Sustainable Solutions with Bio-Organic Catalyst here.

Benefits Include:

- Elimination of odors

- Increased dissolved oxygen (DO)

- Reduces energy usage

- Eliminates floating grease build-up

- Reduces volatile organic compounds (Hydrogen Sulfide, Ammonia, Amines, Ketones and Mercaptans

- Reduces sludge volumes

- Reduces BOD (Biological Oxygen Demand), TDS (Total Suspended Solids) and COD (Chemical Oxygen Demand)

- Enhances biological processing (BNR)

- Cleans collection system (Odors, Slime & FOGs)

- Breaks down organic binders & mineralization (Struvite)

- Reduces oxidation chemicals

- Cleans concentrated animal feedlot operations (CAFO) lagoons

- Substantially eliminate H2S gases and odors

- Treat upstream TKN/BOD loadings (Active pre-treatment of sewage)

- Reduce chemical costs

- Much safer than harsh and toxic chemicals

Products: