Paper and Pulp – Environmental Solutions

Bio-Organic Catalyst has introduced a green, non-toxic, chemistry model that combats slime formation, and its problems in paper processes, replacing the toxic biocides normally used in papermaking processes.

Papermaking processes use a huge amount of water, with most of it recirculating throughout the system. Recirculation increases the content of soluble and insoluble organic waste materials that are found in the raw pulp, including wood fiber fines, starch, organic polymers and others.

Due to this abundance of organic wastes within the paper process water, a microbial broth forms which fosters the development of a culture of microorganisms, especially slime producing bacteria. This slime can grow abundantly and stick all over the wet end section machinery, including the white water pit, head box, pipe slow flow sites such as elbows, low vacuum boxes, and every dewatering element.

Instead of being a bacterial killer, like normal biocides, BOC eliminates the formation of biological film growth by increasing oxygen transfer rates within the process water and by elevating the dissolved oxygen levels in water. The BOC technology deploys very fine micro-bubbles that will attach themselves to the protective microbial structure of biofilms and cause them to dissolve.

The ability of BOC bio-catalytic formulations to increase oxygen transfer rates has been proven scientifically, and is also a key factor in eliminating odors and enhancing aerobic biological conditions in water bodies, both important factors in paper manufacturing, where smells and lagoon discharge treatment are critical operational issues, especially in those processing recycled fibers.

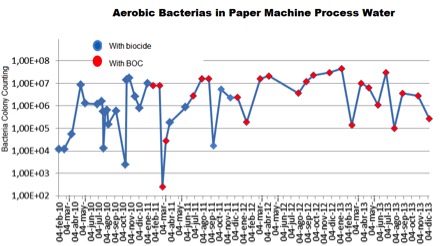

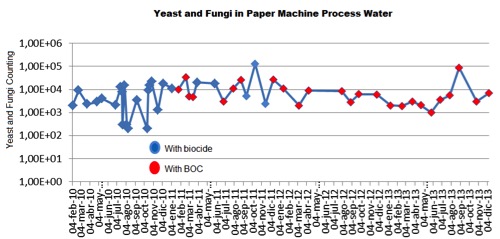

The bio-catalytic capabilities provide a broad spectrum of chemical bonds cleavage pathways by enzymatic mechanisms. This enables the bacteria counts to remain as low as when using normal biocides, as can be seen in Figure 1.Machines producing paper from recycled fibers (test liner, corrugating medium, tissue, etc.) can be kept clean and free of slime by adding BOC to the process water. BOC also benefits the wastewater treatment process by accelerating the oxidation mechanism. It will increase the efficiency of the BOD-COD degradation process.

Figure 1- Aerobic bacteria, yeast and fungi counting in process water from a paper machine producing test liner and corrugating medium (100% recycled fiber material) when normal biocide and BOC was added.

Benefits Include:

- Eliminates the formation of biological film.

- Increases oxygen transfer rates.

- Reduces manufacturing downtime for cleaning.

Product: