NONTOX® – Bio-Catalytic Treatment of Petroleum Hydrocarbons

NONTOX® is a powerful bio-catalytic agent for cleaning TPH (Total Petroleum Hydrocarbon) from soils and all hard surfaces.

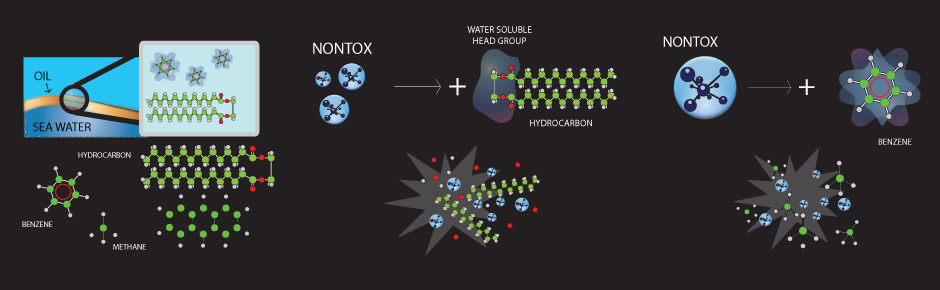

NONTOX® releases the TPH pollutants in a form more compatible for microbial remediation.

NONTOX® stimulates natural biological reactions within indigenous microbial ecosystems through enhancement of oxygen transfer, thereby supporting accelerated remediation rates of the TPH pollutants.

NONTOX® will treat virtually all TPH pollutants, including, crude oil, jet fuel, and diesel oil.

- Enhances remediation of TPH (Total Petroleum Hydrocarbons).

- Provides excellent surface cleaning of TPH components.

- Treats all types of petroleum hydrocarbon contamination.

- Helps in the precipitation of metals in wastewater discharges.

- Reduces time associated with soil and water remediation and cleanup.

- Provides immediate and ongoing VOC (Volatile Organic Compounds) suppression.

- Reduces fire hazards, increasing flash point, and auto ignition threshold points, in gasoline or fuel oils.

- Does not require personal protective equipment.

NONTOX® is fully compatible with all application equipment, including; hand or power sprayers, helicopter, airplane, and floating equipment. NONTOX® requires no special personnel protective equipment.

![]()

Click on a title below to watch videos on NONTOX.

DIRECTIONS

NONTOX® may be applied to TPH contaminated soil, shorelines and beaches at dilutions of 0.2% – 2%. Rates of application will vary with TPH concentrations, equipment specifications, and soil types.

For general dilution ratios, use a mixture of 4 gallons (15.2 liters) of water with 1 gallon (3.8 liters) of NONTOX® to treat 1 cubic yard (1 cubic meter) of contaminated soil.

NONTOX® should be allowed to soak for up to 30 minutes to maximize contact time on heavily coated surfaces. Type of power washing system will determine optimum dilution rate.

Cleaning Dilution:

For Light Cleaning: Use 1 part NONTOX® per 256 parts water.

For Heavy Cleaning: Use 1 part NONTOX® per 50 parts water.

Conditions for Use: Water salinity does not negatively affect product performance. Water temperature under 2°C can affect product performance. Aged or highly viscous concentrations of hydrocarbon may require presoaking prior to removal.

Flammability: None

Shelf Life: Maximum 2 years.

Special Handling and Worker Precautions for Storage and Field Application: None

Skin, Eye and Hand Contact: Use of protective eyewear and rubber gloves is recommended under normal GMP’s.

Ventilation: None required.

Respiratory Protection: None required.

Maximum and Minimum Storage Temperatures: Maximum temp: 50°C, Minimum temp: 2°C.

- NONTOX® Label Info

- Nontox® Label Info – Spanish

- NONTOX® Product 1 Sheet

- US Safety Data Sheet NONTOX®

- EU Safety Data Sheet NONTOX®

- Canada Safety Data Sheet Nontox®

- Technical Analysis Paper, Use of NONTOX® to Eliminate Emergency Oil Spills

- NONTOX® Technical Brochure

- Bioremediation Presentation

- Research Article: Effectiveness of a bio-catalytic agent used in the bioremediation of crude oil-polluted seawater