Improving the Quality of Life, Improving the Facility Manager’s Bottom Line

Improving the Quality of Life, Improving the Facility Manager’s Bottom Line

The development of Bio-Organic Technology is a fundamental breakthrough in addressing the chronic environmental challenges that perplex nearly every facilities manager. Bio-Organic Technology provides a way to lower critical operating costs by alleviating expensive maintenance procedures, while improving the quality of life within their facilities.

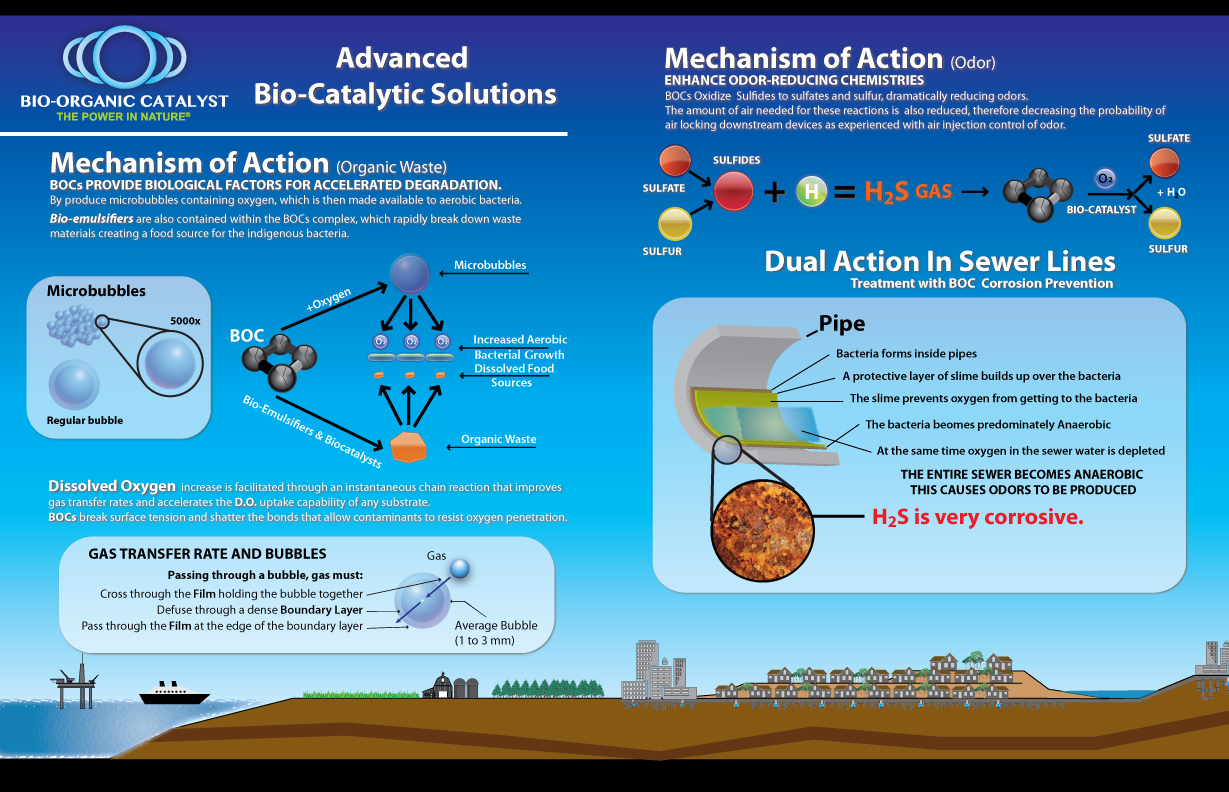

This technical breakthrough is based upon a new understanding of how to utilize bio-catalytic actions upon organic wastes. Bio- Organic Technology provides the biological factors for accelerated degradation. Unlike enzymatic and bacterial products, Bio-Organic Technology introduces micro-bubbles, containing oxygen, into the system, which is then made available to aerobic bacteria. By accelerating the transfer of oxygen gas exchanges, an essential and fundamental catalyst of ecological restoration, Bio-Organic Technology acts directly on nature’s own inherent restorative mechanisms to obtain ultra-clean facilities.

Bio-Organic Technology also contains Bio-Emulsifiers, which rapidly breakdown waste materials creating a food source for indigenous bacteria. Bio-Organic Technology works through a unique ability called ‘beta-oxidation’, which acts across the entire spectrum of organic structures, causing them to break apart into their constituent components (Hydrocarbons are broken down into carbon dioxide and water!). The greater transfer of oxygen across membrane barriers, such as rotting organic wastes, renders noxious odors neutralized on contact. Bio- Organic Technology eliminates the drawbacks and limitations of enzymatic and bacterial products, i.e incompatibility with sanitizing agents (bleach or hypo chloride), temperature ranges, and application restrictions. Additionally, Bio- Organic Technology is much safer and is non-irritating and non toxic to all human, animal and marine life.

Cleaning – Don’t Just Clean – Remediate

Traditional cleaners can leave toxic residues which in some cases lead to skin irritations, and reoccurrence of pathogen growth. Bio-catalytic cleaners have been shown to be extraordinarily effective in treating the most difficult waste pollutants, specifically fats, oils, greases, and hydrocarbons. They unlock a two-fold cleaning sequence: 1) Wastes are naturally solubilized (bio-catalysis – broken down into constituent components), and 2) accelerated gas transfers provide a deep cleaning effect of the pollutants. The resulting benefits are that surfaces, substrates, drain lines, interceptors, garbage dumpsters, etc. are very deeply cleaned and odor free, leaving behind no residual elements.

Odor Control

The greatest challenge in facility management is nearly always linked to septic conditions that are the breeding ground for pathogenic organisms that cause infections and sickness. These same conditions are the source of chronic odors when organic wastes are left behind in substrates of floors and fine cracks, which cause low levels of a background scent. This is very prevalent in bars, pubs, restaurants, kitchens, drains, meat rooms, and bathrooms.

Hydrocarbon Remediation

Bio-Organic Technology cleaves the ester bonds in long chain fatty acids and Hydrocarbons and reduces these pollutants to their constituent components, carbon dioxide and water. Used by facilities to clean up accidental spills and also for drywell treatment. Over time, drywells become “capped” by grease and oil runoff. They are unable to leach the water collected into the soil and floods ensue. Bio-Organic Technology breaks down these “caps” to facilitate the free flow of run-off water in parking lots. Municipalities regularly check drywells for hydrocarbon levels. Stay in compliance using Bio-Organic Technology. Eliminates hydrocarbons from being released into our water supply.

Floors and Drain Lines

A dirty, greasy floor is dangerous. A cleaner surface is safer. The use of Bio-Organic Technology can not only make your facility safer, but improve your bottom line. Use Bio-Organic to clean the substrates and fine cracks in your floor and then squeegee the waste water into the drain. Bio-catalytic cleaners break down the fats, oils, and greases that cause so many issues in drain lines, but they offer much more flexibility in that they can be combined with sanitizers. They keep working all the way to your Grease Trap, breaking down fat, oils and grease so pump outs are less frequent and eliminate the odors that emanate from the trap. Who hasn’t got a whiff of the grease trap on their way into a fine restaurant? Not the first impression you want to make!!!

Breaks Down Bio-Films and Organic Binders

Bio-Organic Technology breaks down organic binders which eliminate biofilms and mineralization. Used in cooling towers to break-down biofilms where pathogens are protected. Often described as the ultimate dispersant, it can be used in conjunction with biocides for a thorough cleaning of all nooks and crannies in the system. The water in pools and fountains is rendered crystal clear, while using less chlorine. Small orifices cannot get clogged with bio-films.

Reduces Exposure to Toxic Chemicals

Protect your personnel and occupants. Consumers and facilities managers have become educated to the toxic and detrimental longterm effects of traditional cleaning agents to people’s health due to the extended exposure of toxic chemicals, but are also required to meet stringent standards across a wide variety of areas in maintaining optimum facilities’ hygiene. Less toxic than traditional cleaning chemicals and no special equipment is required for deploying B-O-T.

Bio-catalytic cleaning products are successfully being deployed in major industry sectors, such as pulp and paper, utilities, food processors, municipal sewage systems, as well as, supermarket meat rooms and oil spill remediation projects. Their powerful ability to rapidly break down pollutants and wastes offers new innovative solutions to the most challenging environmental issues of major industry sectors.

The result is a remarkably refreshed atmosphere created for employees and customers alike, where deep cleaning of problematic areas within a facility is done, especially drains and areas of moisture. Longer term, the residues that accumulate on surfaces are removed, and drain lines are kept clean and free flowing. Floors are cleaned so deeply and thoroughly that they look much like the day they were acquired. Odors are not only eliminated, but the conditions that cause odors to evolve are eliminated and restored. Overall, Bio-Organic Technology is sure to bring a (green) revolution to the most critical aspects of facilities’ cleaning management. For additional information please visit www.bio-organic.com. Follow us on Twitter @BioCata and “Like” our Facebook page at Bio-Organic Catalyst.

Click here to download the article.