BOC Reduces Viscosity and Returns Homeostasis

During 2019 a staged trial was carried out on a co-digestion site in Leicester. It included supermarket waste, swine waste, dog food and oil washing as feedstock. Careful attention to daily Dry Matter (DM) feeds with daily sampling, as well as the DM, FOSTAC, pH and temperature.

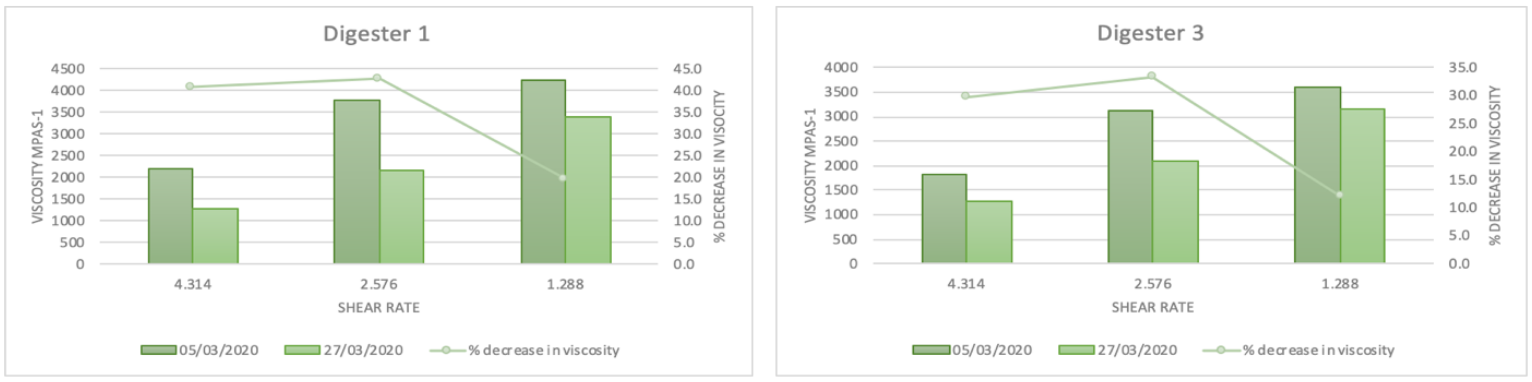

Four weeks after the BOC was re-installed and dosing began, the 21-day viscosity results are back. Digester 1 is showing the most significant reduction of over 40%, Digester 3 a little less, however still statistically relevant of 33%.

This is good news for the operation. Comments and observations from the operators are encouraging, and recent results of biological indicators suggest a return to normality.

A further 25% removed COD in a bench-scale trial.

The labs confirmed the high viscosity was caused by one of two things, firstly an overloading (high OLR) or a sudden shock to the system. At the end of last year dosing of the BOC had stopped, this was to evaluate or provide further clarification of the results seen in the trial period, see the full case study here. Organic Loading, however, continued at the same level as through the dosed period. The result of this was the biofilm produced more EPS, (Extracellular Polymeric Substance). The labs confirmed the high presence of lipoprotein in the EPS; the feedstock is characterised by high levels of Fats and protein.

BOC, firstly, will prevent excessive build-up of the EPS, a certain amount is required, at the initial hydrolysis phase. Secondly, it will dissolve more organic solids into the liquid phase, increasing the metabolic energy. And thirdly, BOC can dissolve the lipoprotein.

It is a technology that will provide homeostasis to the process and at the same time optimise the biological digestion of the waste and maximise gas output both quantity and quality.

Click here to read the full case study, BOC Dissolves Lipoprotein (Eps) Concentration In A Digester Reducing Viscosity.

This Post Has 0 Comments