Parker D. Dale has spent decades advancing a nature-aligned…

Turning Food Waste into Value: Boosting Lactic Acid with Cavitation & Biocatalysts

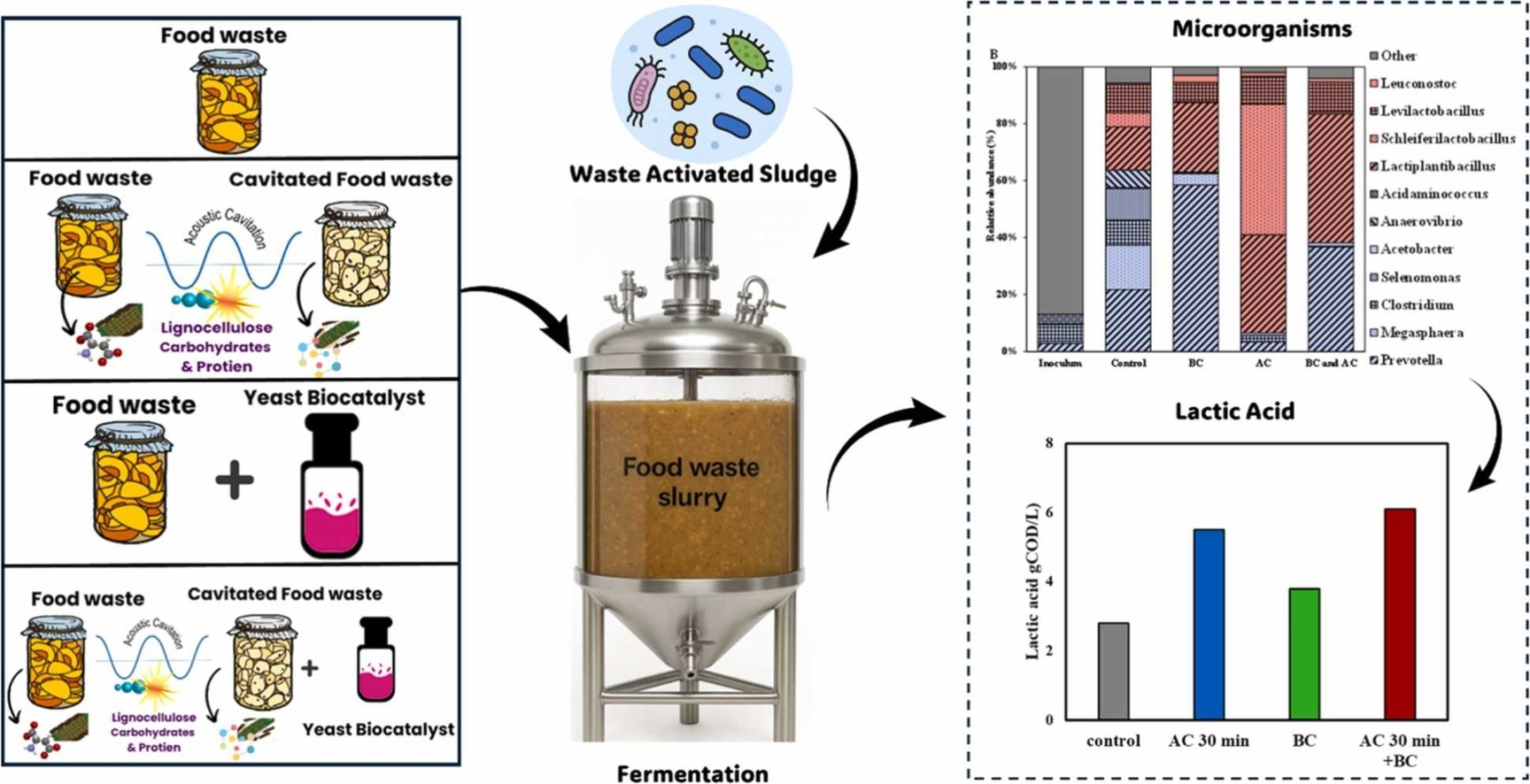

Transforming Food Waste into High-Value Lactic Acid with Cavitation and Biocatalysts

Food waste is one of the world’s most abundant—and most underused—resources. Every day, tons of discarded produce, kitchen scraps, and processing leftovers end up in landfills, where they generate methane and contribute to environmental strain. But what if this organic material could be transformed into something valuable? A recent case study from Bio-Organic Catalyst demonstrates exactly that, showing how innovative processing methods can dramatically enhance lactic acid production from food waste.

Lactic acid is a versatile compound used across industries—from food and pharmaceuticals to biodegradable plastics like PLA. Traditionally, producing it efficiently from heterogeneous food waste has been a challenge due to inconsistent substrate quality and microbial competition. The study explored a new approach combining acoustic cavitation and bio-catalytic enhancement to overcome these limitations.

Cavitation: Unlocking the Waste Stream

Acoustic cavitation uses high-frequency sound waves to generate microscopic bubbles that collapse with significant energy. When applied to food waste for a short, 30-minute treatment, cavitation significantly increases the solubilization of the organic material. In simpler terms, it breaks down structures and makes nutrients more accessible—creating a more digestible substrate for microbes.

The case study found that this step alone made a dramatic difference in how efficiently the waste could be converted into lactic acid.

Bio-Catalysts: Guiding the Microbial Community

To further enhance production, the research incorporated a yeast-extract bio-catalyst. Its impact was twofold:

-

Suppressing competing pathways that produce undesirable byproducts

-

Stimulating lactic-acid–producing bacteria and improving overall metabolic efficiency

With both cavitation and the bio-catalyst at work, the microbial community shifted toward species that naturally maximize lactic acid output.

A Dual-Process Solution for the Circular Economy

The combined method resulted in higher lactic acid yields, fewer unwanted byproducts, and a more stable fermentation process. It’s a promising blueprint for turning organic waste streams—whether from municipal programs, food processors, or agricultural operations—into profitable biochemical resources.

As industries seek more sustainable, circular solutions, this approach highlights how innovative processing can unlock new value from materials that would otherwise be discarded. By pairing physical and biological enhancement, the study demonstrates a scalable pathway for producing high-value chemicals while reducing environmental impact.